Oil Chemical Industry Steam Boiler

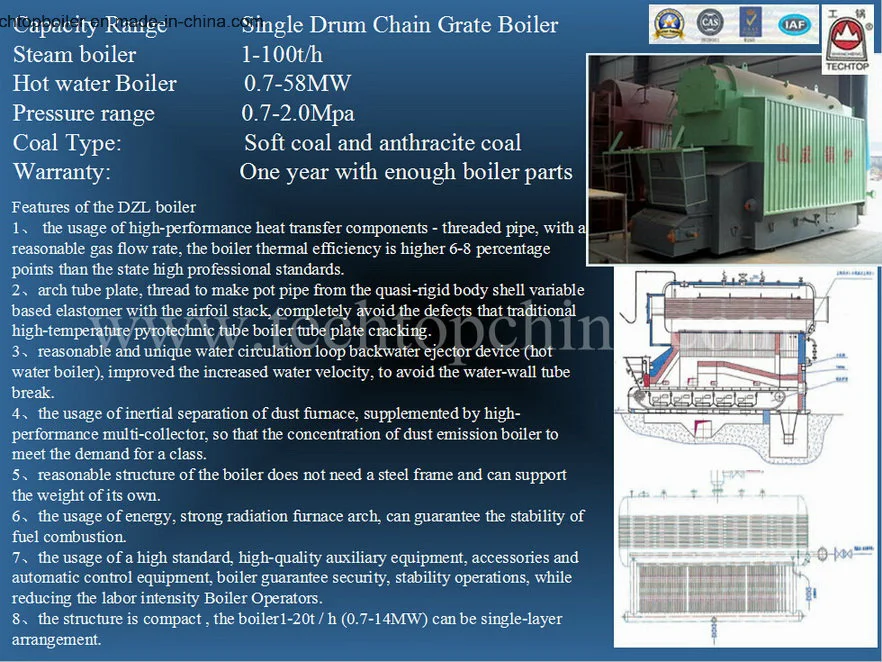

Features of the DZL series boiler 1, the usage of high-performance heat transfer components - threaded pipe, with a reas

Basic Info.

| Model NO. | Oil chemical Industry |

| Drum Placement | Horizontal Boiler |

| Pressure | High Pressure |

| Manufacturing Level | B |

| Burning Style | Chamber Combustion Boiler |

| Usage | Industrial |

| Warranty | 1 Year |

| Transport Package | GB |

| Specification | ISO9001 |

| Trademark | TECHTOP |

| Origin | China |

| HS Code | 8402120090 |

| Production Capacity | 450sets |

Product Description

Features of the DZL series boiler1, the usage of high-performance heat transfer components - threaded pipe, with a reasonable gas flow rate, the boiler thermal efficiency is higher 6-8 percentage points than the state high professional standards.

2, arch tube plate, thread to make pot pipe from the quasi-rigid body shell variable based elastomer with the airfoil stack, completely avoid the defects that traditional high-temperature pyrotechnic tube boiler tube plate cracking.

3, reasonable and unique water circulation loop backwater ejector device (hot water boiler), improved the increased water velocity, to avoid the water-wall tube break.

4, the usage of inertial separation of dust furnace, supplemented by high-performance multi-collector, so that the concentration of dust emission boiler to meet the demand for a class.

5, reasonable structure of the boiler does not need a steel frame can support the weight of its own.

6, the usage of energy, strong radiation furnace arch, can guarantee the stability of fuel combustion.

7, the usage of a high standard, high-quality auxiliary equipment, accessories and automatic control equipment, boiler guarantee security, stability operations, while reducing the labor intensity Boiler Operators.

8, the structure is compact, the boiler1-20t / h (0.7-14MW) can be single-layer arrangement.

Capacity: 1t/h, 2 t/h, 4t/h, 6t/h, 8t/h, 10t/h, 12t/h, 15t/h, 20t/h, 25t/h, 30t/h, 35t/h, 40t/h, 44t/h and mor., Rated evaporated pressure: 1.25 MPa, 1.6MPa and more. Steam can be saturated steam and superheated steam, 1~6 t/h is peckage, 6~10 t/h is shop- assembled, 15~30 t/h half shop- assembled, 35~44 t/h is field assembled.

| DZL4-1.6-A II | DZL6-1.6-A II | DZL8-1.6-A II | DZL10-1.6-A II | DZL15-1.25-A II | DZL20-1.6-A II | DZL25-1.6-A II | DZL30-1.6-A II | ||

| (t/h) Rated evaporation capacity | 4 | 6 | 8 | 10 | 15 | 20 | 25 | 30 | |

| (Mpa) Rated working pressure | 1.6 | 1.6 | 1.6 | 1.6 | 1.6 | 1.6 | 1.6 | 1.6 | |

| (C) Rated steam temperature | 204 | 204 | 204 | 204 | 204 | 204 | 204 | 204 | |

| (C) Feed water temperature | 20 | 150 | |||||||

| (MM) Radiation heating area | 12.24 | 19.2 | 22.1 | 24.15 | 34.5 | 53.7 | 99.2 | ||

| (MM) Convection heat area | 89.55 | 115.3 | 128 | 168.2 | 339.9 | 411.8 | 457.8 | 628.6 | |

| (MM) Economizer heat area | 28.16 | 52.3 | 52.8 | 130.8 | 150.4 | 188 | 295 | 413 | |

| (MM) Grate effective area | 5.18 | 7.7 | 9.07 | 11.53 | 16.24 | 22.84 | 24.7 | 26.88 | |

| Suitable coal type | A II | ||||||||

| (kg/h) Coal consumption | 615 | 870 | 1153 | 1440 | 2165 | 2868 | 3550 | 4254 | |

| (%) design thermal efficiency | 78.45 | 77.26 | 80.63 | 79.7 | 80.5 | 81.1 | 81.2 | 81.5 | |

| Max transport (××)(m) | 7.06×2.96×3.60 | 7.60×2.95×3.70 | 7.34×3.00×3.70 | 7.20×3.50×3.70 7.50×2.30×2.60 | 7.33×3.37×3.70 8.90×3.37×2.50 | 7.81×3.37×3.51 9.44×3.77×2.60 | 8.47×2.60×2.74 12.00×8.02×8.90 | 9.00×2.60×2.85 12.00×8.20×9.70 | |

| (t) Max transport weight | 30 | 42 | 46 | 25/18.5 | 27/25 | 29/28.5 | 31/33 | 35/36 | |

Send to us